How Custom Extrusion Manufacturer can Save You Time, Stress, and Money.

Wiki Article

Plastic Extruded Profiles Things To Know Before You Get This

Table of Contents5 Easy Facts About Custom Plastic Extrusions DescribedThe Custom Plastic Profiles PDFsThe Greatest Guide To Extruded Plastic ProfilesAll about Custom Extrusion ManufacturerGetting My Custom Plastic Profiles To Work

We can also supply customized laminations and also would enjoy to send you examples upon demand. We currently have seven lamination terminals that can manage lots of different types of personalized plastic extrusions. We offer custom-made packaging and also are currently packaging an extruded account item that is sold to a "Huge Box" Firm.Be it basic, complicated, hollow, coextruded, or printed, our group of specialists can customize it for you. Additionally, our experts recognize that no two jobs coincide as well as we plan to maintain it in this way. This suggests that right here at Keller Products we can use you any type of number of products for your layout requires.

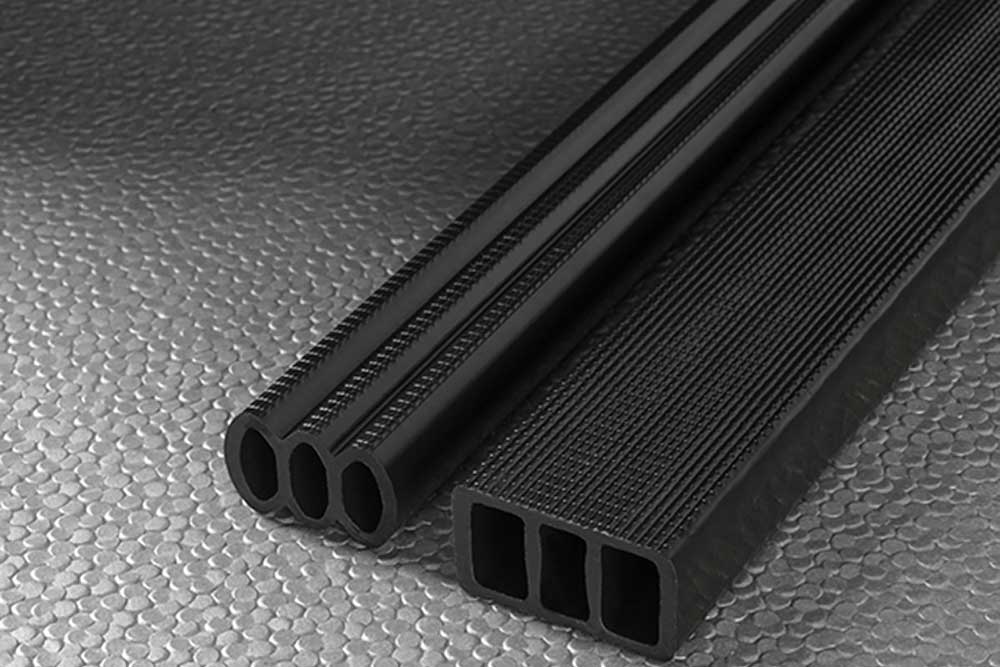

Custom extrusions are tailor-made items that are produced forcibly raw products via a die or mold and mildew. This process is understood as extrusion. Extrusion is made use of to produce things of a dealt with cross-sectional profile, such as pipes, tubing, and also poles. The raw material, known as the "extrudate", is initial softened by heating.

Extrusion can be utilized to produce items from a range of materials, consisting of steels, plastics, as well as compounds. It is made use of in a selection of markets, consisting of vehicle, construction, as well as production.

Some Known Details About Custom Extrusion Manufacturer

There are several business that sell this kind of manufacturing. These business can aid you to make the best product for your requirements as well as then create it making use of the extrusion process. If you have a requirement for tailor-made items, custom-made extrusion relevant handling may be the ideal remedy. Prototyping your next essential project can be as very easy as getting in touch with Alpha Customized Extrusions, Inc.Additionally, Alpha Customized Extrusions, Inc. offers a host of second capabilities to complete your complete task. Call today!.

Consist of joints, seals, top coats, multiple shades and other functions

The Definitive Guide for Custom Plastic Profiles

Lead times differ based on our Finite Ahead scheduling system. Our invoice of your order starts the scheduling procedure. Is all tooling generated in-house? Yes, all tooling is developed and manufactured by Sandee. What is the basic preparation for a production order? The dynamics of custom-made production frequently lead to quick modifications to tooling, manufacturing and fabrication schedules.

Just how long does a custom-made color match take? It normally takes 10 functioning days to get a color chip to you for approval, as well as ten additional functioning days to generate the custom-made shade concentrate from the accepted color chip.

They are listed in order of preference. DWG Car, CAD 2000 DWG Any modification of Vehicle, CAD DXF Automobile, CAD 2000 DXF Any alteration of Automobile, CAD Please speak to if you can not submit the documents in one of these layouts (https://packersmovers.activeboard.com/t67151553/how-to-connect-canon-mg3620-printer-to-computer/?ts=1667541302&direction=prev&page=last#lastPostAnchor). What is the optimum feasible width of an account? The extrudable profile is determined by measuring its established size.

Things about Extrusion Of Plastics

We've been doing it right given that 1962 and are positive that your task will take advantage of our in-depth experience in:. custom plastic profiles. https://www.huntingnet.com/forum/members/k3ll3rpl4st8.html.NCS also offers co-extruded products of various durometers and various materials that are co-extruded into the exact Bonuses same component. If you have questions about co-extrusions or any of our extruded plastic products, please reach out to our group to find out extra - custom plastic extrusion manufacturers.

Extruded plastic forms are developed using a high-volume production process where raw plastic resin product is melted, after that required through a die to form a constant account. To produce plastic extruded forms, the material is positioned into the barrel of an extruder after that gradually thawed. Warmth and pressure is after that used to require the molten plastic into a die.

Not known Facts About Plastic Extrusion Companies

With simply a small modification, extrusion molding can go from producing complex shapes to plastic sheets. After plastic leaves the extruder, it stays warm and can be further adjusted. This enables suppliers to modify the shape of extruded plastic making use of rollers, footwear, or dies to fulfill the particular needs of many applications.Extruded plastics are made use of throughout commercial and also commercial applications, with some of the most common being tubing, poles, as well as specialty accounts. Applications for extruded plastic tubing, poles, and specialized profiles include:.

Ask us to resolve your issues and also count on us for precision as well as on-time distribution.

At Astro Plastics, our period in the industry and variety of top-end abilities allow us to deliver on also one of the most intricate customer demand. Our team of experts works closely with you to tackle your personalized plastic extrusion requires from concept to conclusion, seeing to it you get the appropriate item at the right time.

Report this wiki page